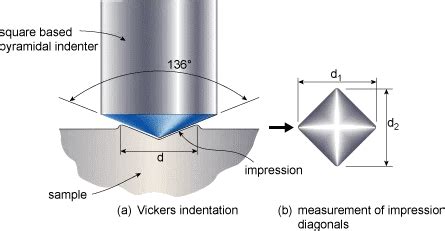

vickers hardness test used in industry|vickers hardness testing machine diagram : discounter The Vickers hardness test is a method of measuring the hardness of a material by indenting it with a diamond indenter in the shape of a right pyramid with a square base and an angle of . Leia os último artigos e notícias da Revista Oeste sobre Eleiç.

{plog:ftitle_list}

webEbony Mystique, ZmeenaOrr, lesbianas, megas ass, fat ass, big black ass, culo grande culona, ebony, negras, lesbians, onlyfans, only fans, bbw, buaty tetas grandes, Watch the porn video of Ebony Mystique gets turned on by Zmeena Orr's fat ass on XOrgasmo.com, where you will find the widest variety of FREE XXX in all the categories.

The Vickers hardness test can measure a wide range of hardness values, from very soft materials to extremely hard ones. This makes it suitable for testing materials with a wide range of mechanical properties, including those used in .The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .The Vickers hardness test is used across various industries for different applications. Metallurgy: To determine the hardness of metals & their alloys. Manufacturing: In quality .The Vickers hardness test is a method of measuring the hardness of a material by indenting it with a diamond indenter in the shape of a right pyramid with a square base and an angle of .

The Vickers procedure can be used to test the hardness of metals and other equally hard materials. However, it was primarily designed to focus on softer materials like plastic specifically on their ability to resist .Find an overview of the Vickers methods and their applications depending on the load range as well as an explanation how to choose the right test load.

The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the . The Vickers hardness test is based on the principle of indentation hardness, where a diamond indenter with a square-based pyramid shape is pressed into the surface of the material under a specified load.The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) .

Vickers hardness testing is a preferred method for assessing the hardness of all types of metals, offering the most comprehensive range of hardness scale measurements .In the Vickers hardness tests, both diagonals of the indent are measured and the average value is used to compute the Vickers hardness number (HV) (Fig. 4 A). In the Knoop hardness tests, only the longer diagonal is measured and the Knoop hardness is calculated based on the projected area of the indent divided by the applied force.

The Vickers hardness test, an offshoot of the venerable Brinell test, has been used since the early 1920s. Although the concept of using one test method to cover a wide range of materials hasn’t changed much in the .In industry, hardness tests on metals are used mainly as a check on the quality and uniformity of metals, especially during heat treatment operations. . The Vickers hardness test method was developed by Robert L. Smith and . Later, in 1939, an alternative to the Vickers test was introduced by Fredrick Knoop at the US National Bureau of Standards. The Knoop test utilized a shallower, elongated format of the diamond pyramid and was designed for use under lower test forces than the Vickers hardness test, allowing for more accurate testing of brittle or thin materials.

The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. . The Vickers hardness test is an industry-standard method for measuring the hardness of metals, plastic, and ceramics. It can be applied to various .Brinell Hardness The Vickers hardness test utilizes a pyramidal diamond in-denter to create an indentation on the material‘s surface. The diagonals (x and y axis) of the indentation are measured, and . Brinell hardness testing is extensively used in the casting industry to assess the hardness and quality of cast materials, such as cast iron . When it comes to conducting a hardness test, it is important to understand the different methods available and their respective advantages and disadvantages. The most commonly used methods include Rockwell, Vickers, Brinell, Knoop, and Leeb. Rockwell Hardness Test & Formula. Rockwell hardness testing is the most widely used method in .

Vickers Hardness Test. The Vickers hardness test utilises a diamond pyramid-shaped indenter to create a small impression on the material's surface. Taking into consideration the weight of the load, the size of the indentation is measured using a microscope. The Vickers hardness number (HV) is calculated based on the indentation diagonal lengths.ASTM and ISO have provided many standardized conversion scales to help the manufacturing industry. Vickers hardness test is a micro testing method used for some specified cases. Sometimes it becomes necessary to change the hardness value from one scale to another. Here we compare the Vickers hardness method with the Rockwell method and their . Industrial Use: Widely used in the metal industry, particularly for softer metals. Vickers Hardness Test. Uses a diamond pyramid indenter pressed into the material. The size of the indentation determines the hardness. Pros: Applicable to a wide range of materials; more accurate than Brinell for hard materials.Two common hardness tests are used in the industry: the Rockwell scale and the Vickers scale. Both test the surface of a material, but they are used for different purposes. The Rockwell hardness test measures the hardness of all metals except in conditions where the structure of the test sample would cause too much variations, or the indentations formed would be too .

Hardness testing is a fundamental aspect of material characterization, providing valuable insights into a material's mechanical properties and suitability for various applications. Among the different hardness testing methods available, the Vickers hardness test stands out for its versatility, precision, and wide range

The Vickers hardness test was developed by George E. Sandland and Robert L. Smith at Vickers Ltd. in the year 1921, as an alternative to the Brinell method to determine the hardness of materials. This Vickers hardness test is usually easier to use compared to other hardness tests. The reason is the required calculations are not dependent on the size of the indenter.In industry, hardness tests on metals are used mainly as a check on the quality and uniformity of metals, especially during heat treatment operations. . The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the test indentation is very .

A full selection of hardness testers, testing machines, testing equipment and accessories for Vickers, Knoop, Brinell and Rockwell hardness testing from Struers, the world’s leading materialographic and metallographic equipment .When doing a Vickers hardness test the distance between indentations must be more than 3 indentation diameters apart to avoid interaction between the work-hardened regions. Vickers hardness testers are routinely used for testing . Hardness testing is of immense importance for quality assurance in industry. Although the most widely used hardness test methods for metals—Rockwell, Brinell, and Vickers—were developed between 1900 and .

vickers hardness testing procedure

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). . TLT Tech Beat January 2024 Evaluation of the iron and steel industry was made by organizing plants into six categories based on number of years of operation. HIGHLIGHTS . CALL US +31628960992. EMAIL US [email protected . The right hardness test method depends on the material being tested and the specific requirements of the application. . measures the diameter of the indentation. Vickers and Knoop hardness tests use a diamond-shaped or pyramidal indenter, where the diagonals of the indentation are measured, and the hardness value is calculated based on the . The Vickers test became an industry standard due to its accuracy and the ability to test a wide range of materials, from soft metals to hard ceramics. For example, TH710/711 micro- Vickers hardness tester adopts unique precision design of optical, mechanical and electrical characteristics, which makes the indentation image clearer and the .

The Vickers method has the following advantages: The Vickers method can be used with any and all materials and test specimens, from soft to hard, as the procedure covers the entire hardness range.

Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Method: Load Range: Standard: Brinell: 1 kgf–3,000 kgf: ASTM E10, ISO 6506: Rockwell: 15 kgf–150 . Additionally, it addresses industry standards and troubleshooting techniques to maintain accuracy and repeatability in testing. This guide is designed to help you make informed decisions about hardness testing for reliable results and optimal material performance. . The Vickers hardness test measures material hardness by determining the size . Later, in 1939, an alternative to the Vickers test was introduced by Fredrick Knoop at the U.S. National Bureau of Standards. The Knoop test utilized a shallower, elongated format of the diamond pyramid and was designed for use under lower test forces than the Vickers hardness test, allowing for more accurate testing of brittle or thin materials.These Vickers hardness testing instruments can be used to create hardness curves (hardness profile measurements) and hardness maps of complete specimens. ZwickRoell hardness testing instruments for Vickers test according to valid industry standards including ISO 6506 , ISO 6507 , ISO 4545, ASTM E384, ASTM E92 , ASTM E10.

For the Vickers test, both the diagonals of the indent are measured, and the average value is used to compute the Vickers hardness number. For the Knoop test, the length of the indentation along its long axis is used to compute the hardness number. A Customized Software Workflow for Microhardness Testing There are different types of hardness tests that measure the hardness of metal and materials in different scales, Brinell, Vickers and Rockwell. We go into depth about the differences in Brinell, Rockwell, and Vickers Hardness Tests: The Differences Explained. Hardness testing is used by different industries, including oil and gas, to certify .

compression tester auckland

compression tester auto zone

WhatsApp Itajaí - SC. WhatsApp Balneário Camboriú - SC. Site Rei dos Salvados. Horários de Atendimento e endereços. Canal do Rei no Youtube. Vagas Abertas. Create your .

vickers hardness test used in industry|vickers hardness testing machine diagram